Smart lifting

solutions

Bin lifting solutions to drive safety, process excellence and cost savings across a range of industries.

- FLEXIBILITY

- ADAPTABILITY

- RELIABILITY

Excellence comes as standard

Our teams have the in-depth knowledge and understanding to work with businesses across a wide range of industries, to identify how lifting and moving equipment will add value, save time, save money and improve safety.

Ensuring worker safety is more than a tick in a box. Contact us now to see how we can make a difference to your day-to-day processes.

Looking for more information?

+48 698 700 302

Give us a call

EUROPEAN-WIDE

DELIVERY

2-YEAR

WARRANTY

PURCHASE AND

LEASE OPTIONS

Bin lifters

Our core range is designed to fill most requirements. Numerous options make our bin lifters adaptable for a whole host of uses and industries, perfect to fit with your specific needs and processes.

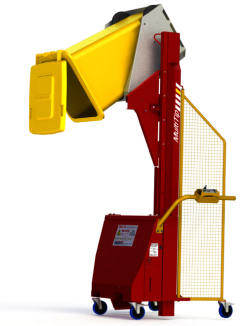

Multi-Tip®

Corrosion-resistant, perfect for indoor and outdoor use

Lifts up to 150kg to heights up to 1.8 metres as standard

Dumpmaster®

Our top-selling mobile wheelie bin lifting system

Lifts up to 250kg to heights up to 3 metres as standard

MegaDumper®

Industry proven system for harsh environments

Lifts up to 600kg to heights up to 6 metres as standard

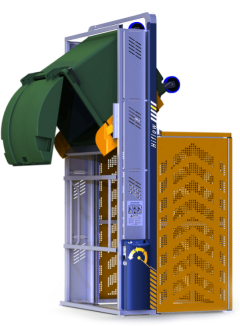

Hiflow®

Static bin-lifter for high volume waste settings

Lifts up to 600kg to heights up to 3 metres as standard

Lifting and moving bins

and crates just got easier

Industry solutions

Construction

Manoeuvrability and robust construction are just two essential requirements for equipment on a building site and are just what Simpro’s bin lifters provide. With the capacity to lift large volumes of waste or move building materials to a height, has seen the adoption of Simpro’s bin lifters across many construction sites.

JRL Plant & Logistics Ltd

“The MegaDumper® has been instrumental for The JRL Group in the reduction of risk from mobile moving machinery on our projects. With its user-friendly operation allowing the projects to empty in excess of a hundred 1100ltr wheelie bins into our 40 yard RORO skips it has reduced time, risk and cost. We look forward to seeing the MegaDumper® in action on all our future projects.”

Manufacturing

Lifting is required across a range of manufacturing processes, from removing waste to tipping ingredients for food preparation. Our specialist team works with you to integrate Simpro’s equipment directly into your processes. Save time, cost and introduce greater safety in lifting requirements.

Paramount Waste Extraction Ltd

“The Simpro Dumpmaster® with its compact design and simple but effective lifting mechanism was the ideal solution to raise the wheeled bins of rejected carton products into the new Ulster Shredder machine at the MM Packaging site in Deeside.”

Waste Management

Hospitals, schools, councils, the list is endless of local authorities where staff struggle daily with volumes of rubbish in bins that need to be emptied. Manually handling heavy bins opens risks of injury and all that brings to the employee themselves and also to their employer. Lifting bins safely is easily introduced.

Holmer Green Senior School

“Transferring waste to our main waste skip has been a problem for a while. We gathered the waste in wheelie bins but then had to manually move it into the main skip which wasn’t ideal. The Simpro Dumpmaster® has made our lives so much easier. A job that was taking up a great deal of someone’s time to complete on a daily basis is now finished in a matter of minutes.”

The proof of the pudding...

Get inspired by the genuine stories of businesses we’ve helped and witness the remarkable difference our services can make.

Our site services team are delighted as the Simpro Dumpmaster is proving to be very reliable and has saved us a fair bit of our R&M budget compared to our previous equipment.

Stuart Coulman

Manager

Chivas Brothers Pernod Ricard

We integrate DumpMasters into our incineration and cremation loading systems seamlessly which makes our offer to the market very competitive.

Dave Morris

Production Manager

Addfield Environmental Systems Ltd

Simpro Europe has made our lives so much easier with the Simpro Dumpmaster we have taken from them.

Lynda Jackson

Holmer Green Senior School

On a busy day we can empty comfortably over 100 bins into our 40 yard skips which means the MegaDumper® really makes a difference with waste management on site.

Stewart Colbert

Logistics Site Manager

JRL Plant & Logistics Ltd

Service and maintenance

Simpro Europe is with you every step of the way when you choose our products. Regular servicing and maintenance of equipment ensures longevity and value for money, and is undertaken by our trained team.

Don’t worry about missing it – we will contact you in good time to schedule a convenient day and time.

Selecting the appropriate bin lifter model is a key factor in ensuring safety and efficiency in waste management, logistics, or industry. To find the device perfectly suited to your needs, several key parameters should be analyzed:

Hooking system: First, identify the type of container you are working with. Are they uniform containers with vertical hooks (so-called "Swiss" or "Belgian"), or "bell" type containers with horizontal hooks? We offer models adapted to both standards, as well as universal (multi-system) versions that handle different container types without the need for reconfiguration.

Capacity and dimensions: Standard containers usually range from 80L to 1100L. Our lifters are calibrated to safely handle both small 120L containers and large articulated 1100L bins.

Body type: It is important whether the lifter should be mounted at the rear of the vehicle (rear-mounted), on the side (side loading), or if it is a stationary waste compactor. Our range includes models dedicated to each of these applications.

Operating conditions: If containers are heavily used, exposed to damage, or have irregular shapes (e.g. construction waste containers), we recommend reinforced models with chain drive that guarantee long service life even in harsh conditions.

Our technical advisors will help you select the optimal model – just provide us with the container type and the vehicle brand on which the lifter is to be mounted.

Safe Working Load (SWL) is a fundamental parameter of every bin lifter, defining the maximum weight of the container including contents that the device can safely lift and empty. Exceeding this value risks damage to cylinders, arms, or even tipping the vehicle.

Our range includes models with different lifting capacities to meet even the most demanding requirements:

Light models (municipal): Designed for standard residential area servicing. Their maximum SWL is typically up to 150 kg. Ideal for 120L, 240L, and 360L containers.

Medium models (universal): The most popular choice for waste collection companies. They feature SWL from 200 kg to 350 kg and easily handle 660L and 1100L containers filled with wet municipal waste.

Heavy-duty models (industrial): Built for handling bulky waste, scrap, or rubble. In this category we offer lifters with SWL from 400 kg up to 1000 kg, equipped with robust guides and reinforced hydraulic system.

Every lifter comes with a factory nameplate showing the exact SWL value. Feel free to contact us for detailed data on a specific model from the catalog.

Discharge height is a critical parameter determining whether waste from the container will be properly dumped into the refuse body (or compactor), or whether some will spill onto the road. That is why we put great emphasis on optimizing the discharge geometry in our designs.

Depending on the model and arm length, our bin lifters offer:

Standard discharge height: Most models designed for standard refuse trucks achieve a discharge height of 1500 mm to 1700 mm (measured from the container pivot axis to the ground). This is sufficient to safely empty 1100L containers into standard-height bodies.

High-lift discharge: For vehicles with raised hopper edges or stationary compactors we offer versions with extended arms that provide discharge heights of up to 2500 mm.

Discharge angle: The tipping angle of the container during unloading is also important. Our designs ensure an optimal tipping angle (often exceeding 45°), guaranteeing complete emptying even of wet and compacted waste.

Additionally, models dedicated to underground or semi-underground containers use special telescopic guides that allow reach and lifting from ground level to the required height.

Yes, absolutely. Safety and legal compliance are our top priorities. All bin lifters we offer are designed, manufactured and tested in accordance with current European Union standards.

CE marking: Every device leaving our production hall is marked with the CE symbol. This is the manufacturer's declaration that the product meets all essential requirements of the New Approach directives, in particular the Machinery Directive 2006/42/EC. CE marking guarantees that the lifter has undergone the necessary conformity assessment procedures.

EU Declaration of Conformity: A detailed EU Declaration of Conformity is attached to every sold lifter. This document uniquely identifies the device (model, serial number, year of manufacture) and lists the harmonized standards (e.g. PN-EN 1501) according to which it was manufactured. This declaration is required for vehicle registration in some countries and by insurers.

Operating manual: Along with the device we provide a complete operating manual in Polish (or English on request), containing guidelines for safe operation, maintenance and lubrication.

By investing in our bin lifters you gain not only a reliable machine, but also full legal safety and user comfort. If needed, we can provide a copy of the declaration even before purchase.